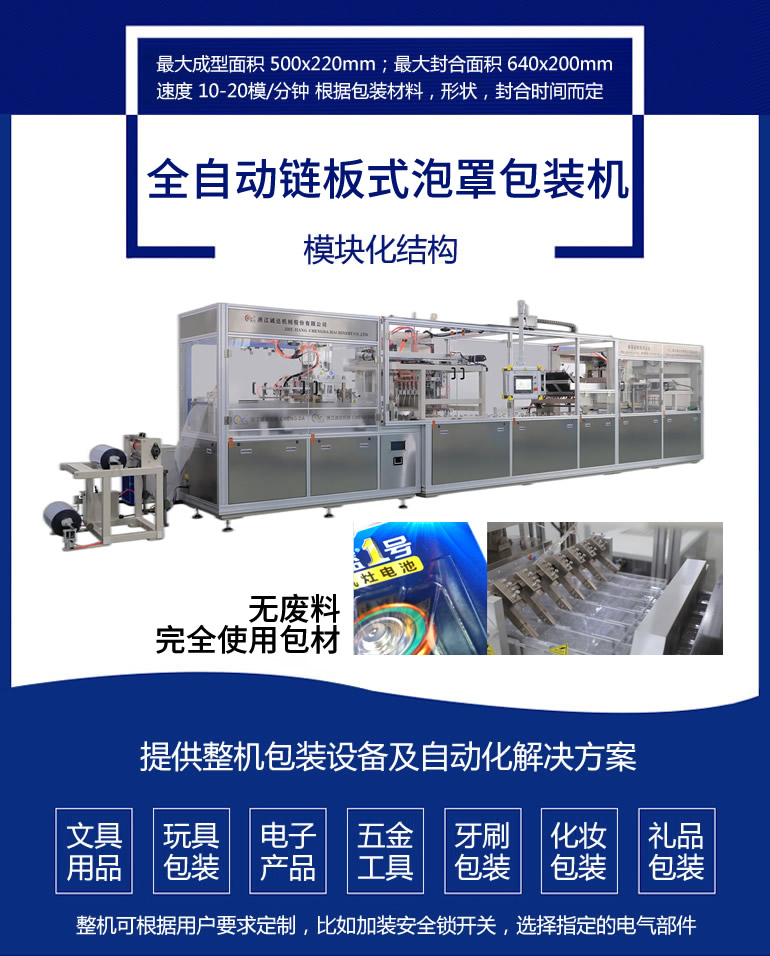

CD-5268 Automatic Blister Machine

CD-5268 Automatic Blister Machine large forming and sealing area.It has wide range of applications,suitable for large batches production.

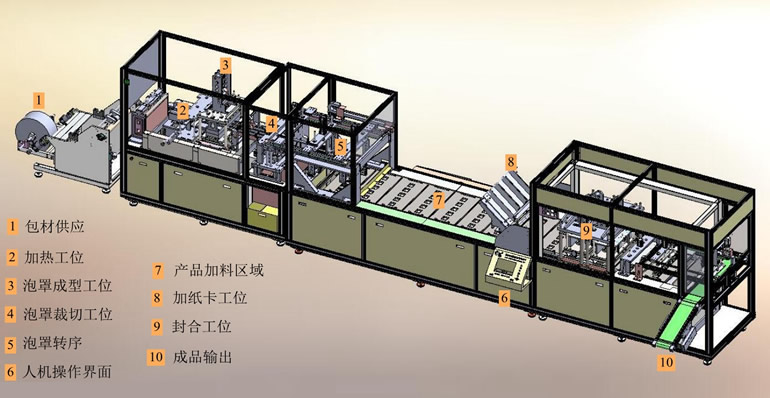

The blister material can be PVC or PET and other rigid materials.Two rolls of materials can be loaded on the material feeding device,save the replacing time and labor.

Use the up and down heating plates for version heating,the material can be heated evenly and steady.

The forming mold can be different types according to the blister size,shape.

The material dragged by servo motor and the forming station driven synchronously,to ensure the machine machine runs continuously.

After the blister formed,use multiple blades for cutting horizontally and vertically,no waste materials,make full use of the material. Compared to the punching mold,it will save 20% materials during the production.

More distance and space offered between the forming section and sealing section,convenient for feeding products or install extra function device.Feeding products can be manually or by special robot.

The sealing station uses two sets heating plates,ensure each package get heated evenly and reduce the sealing period so that improve the total production efficiency.

Output the finished package in the end of the machine,also can be connected to the secondary procedure,such as carton packing,barcode printing.

The whole machine can be custom-made,such as protection door with safety lock,appointed electrical components.

Max.forming area 500x220mm

Max.sealing area 640x200mm

Output: 10-20 cycles/min. According the packaging material,blister shape,and sealing period.

Modular structure

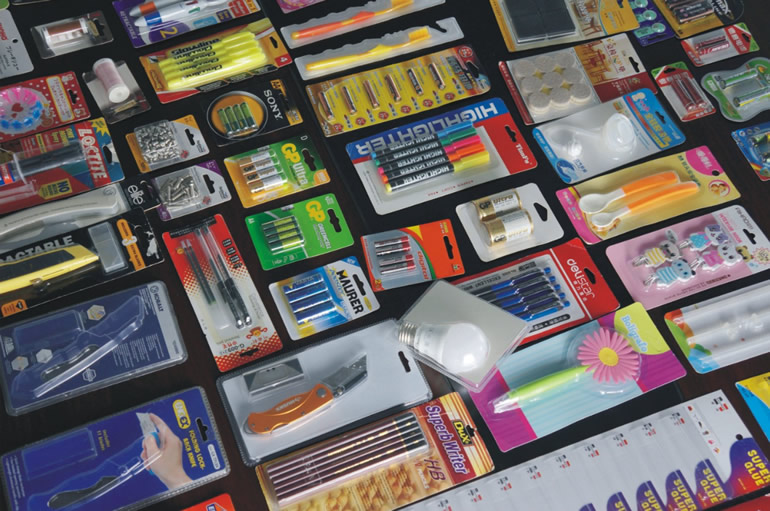

Samples

| Prev:CD-3450 Automatic Blister Machine<Back> |

| Related products |

| ►CD-3450 Automatic Blister Machine |